Countermeasure against deformation in cylinder molded product

Countermeasure against deformation in cylinder molded product

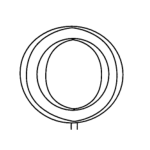

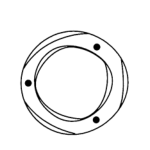

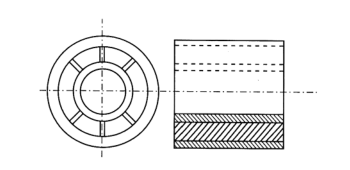

(1) Triple or quadruple-point gate is preferred, since it can directly get in from longitudinal direction. In the

case of the side gate or submarine gate, make the runner go around and prevent the core from falling over by making it two to three points.

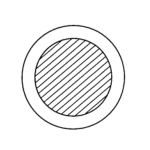

(2) In the case of double cylinder, the rib thickness should be 1/3 of the base, because the joint rib thickness

will affect to the roundness.

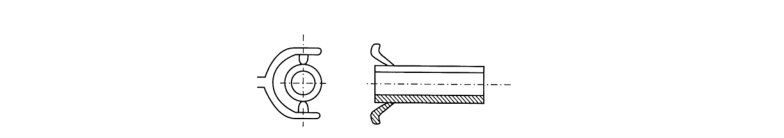

(3) Cooling the core pin is very important element. Other than direct water cooling and heat pipe indirect

cooling, little ingenuity is required such as air cooling or using special material that have good heat conductivity, when the pin is thin.

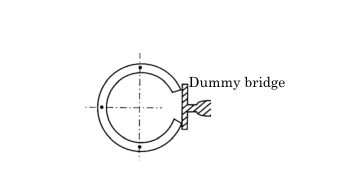

(4) Shape should be all similar in whole circumference. If there is a segmental part, placing a dummy bridge and cut after cooling will be an effective method to prevent falling down.

Figure 3-3 Gate type and roundness of cylinder molded product

Figure 3-4 Making multipoint by runner in submarine gate case