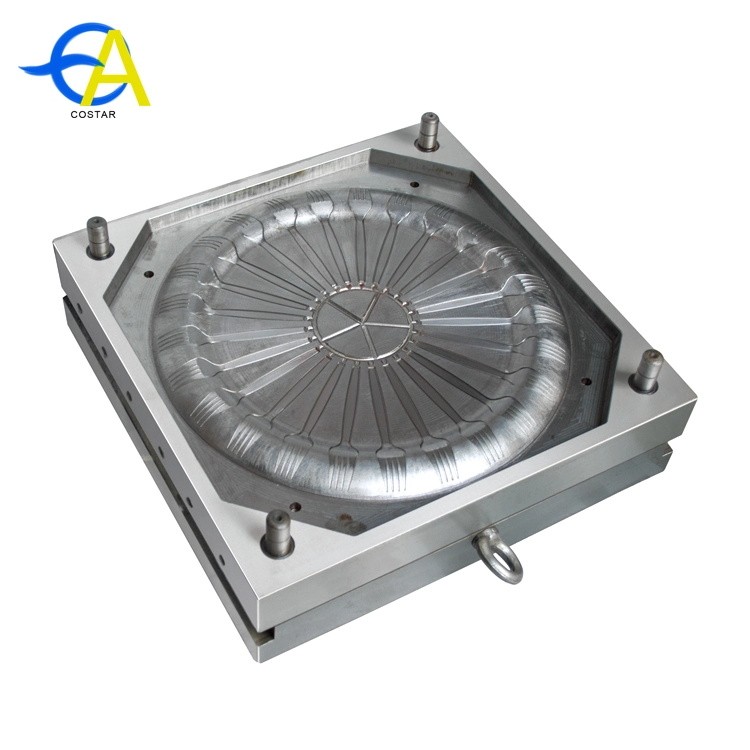

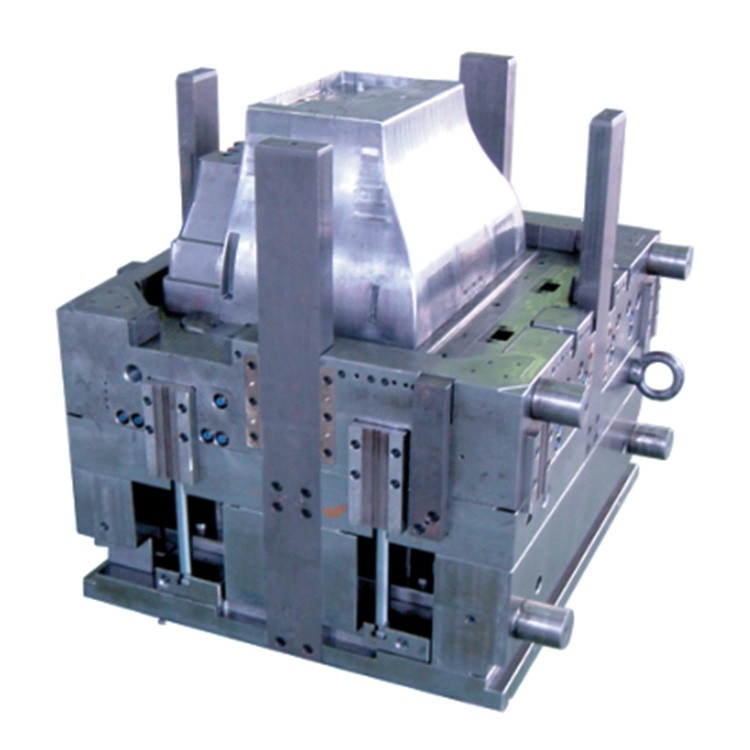

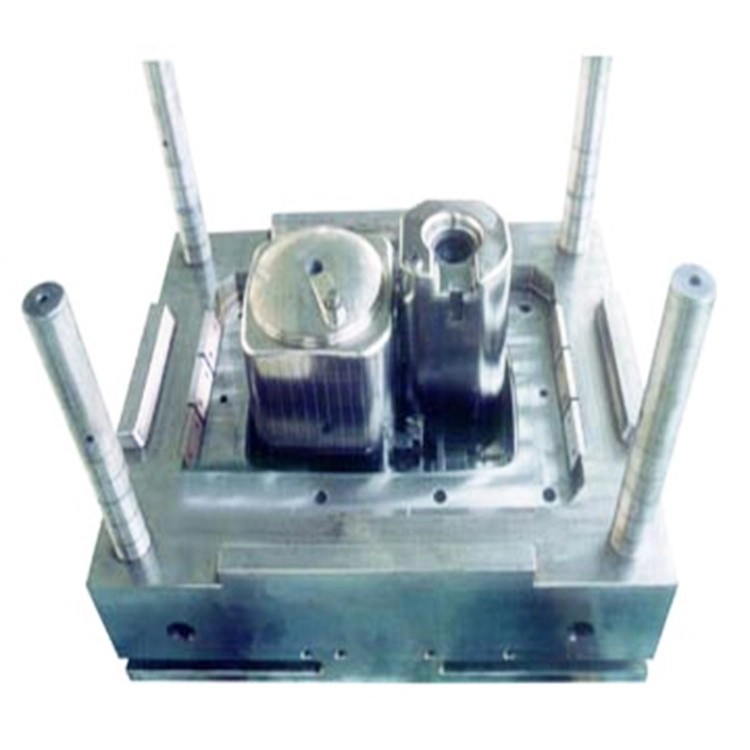

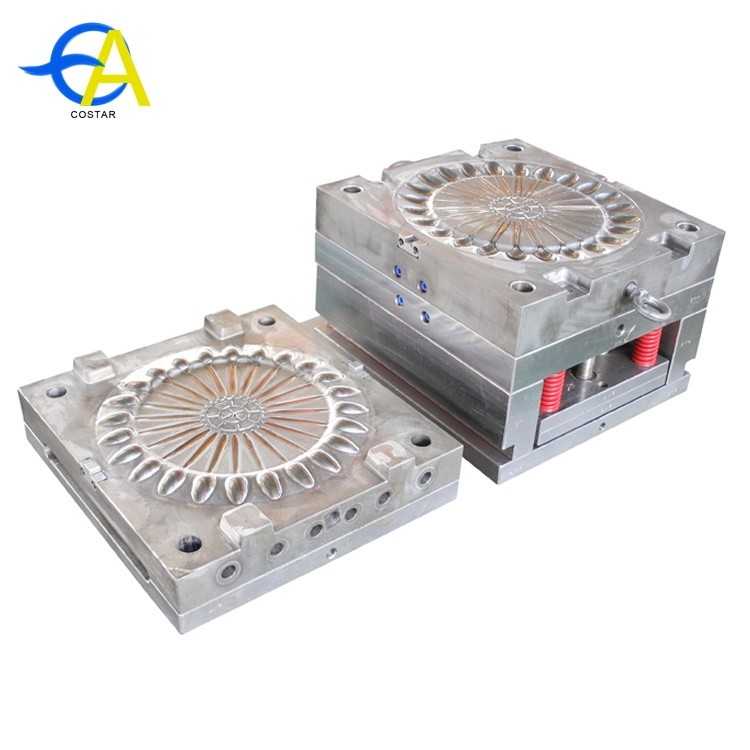

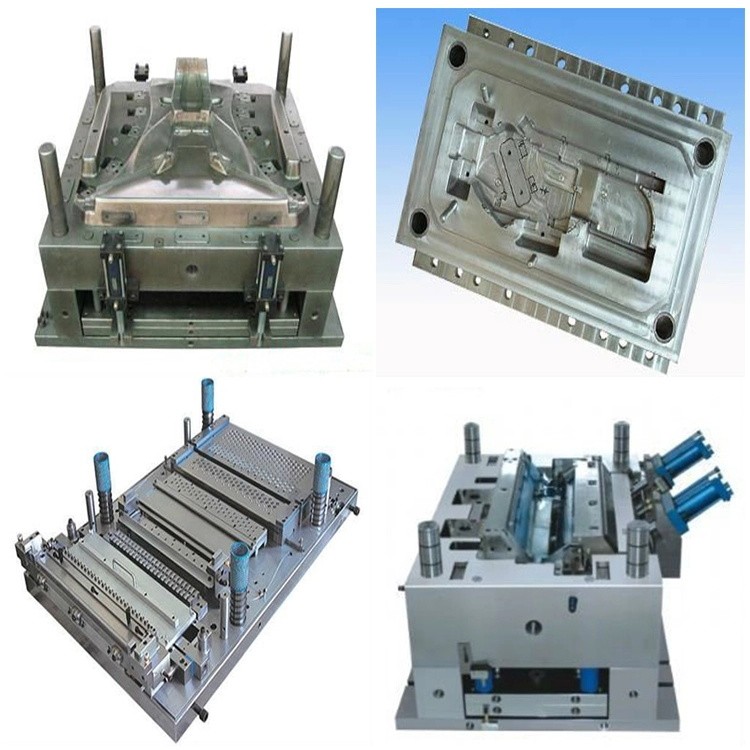

Customized plastic injection home appliance precise air conditioner mold manufacturer

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

Customized plastic injection home appliance precise air conditioner mold manufacturer

| Main Technique Parameters | |

| Cavity/Core Material | 718H, P20, NAK80, 2316, 2738, 2344 |

| Product Material | ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET,PA, PBT, PEI, etc. |

| Base | LKM or by requested |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi cavities by requested (support similar products in one mould) |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | Available SHOTS will depend on the steel material you choose |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Software | CAD, Pro-E, UG, etc |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. |

Machine Feature:

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication, provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould